Modern window production is characterized by the highest competition and the guaranteed victory in this fight will be ensured only by the lowest prices and the best quality. On the one hand product’s prime cost has to be the lowest, on the other — materials have to be qualitative and assembly faultless.

“That’s impossible!” this the first what comes to mind of any expert or the owner knowing production and this opinion is confirmed by a proverb “Cheapest is the dearest”. However, it is worth a closer look at this task. What makes up the sum of expenses on product’s production? The base price includes losses related to defects and accidental design damage, not the most economical and subject to a human factor cutting of profile and glass. Significant funds worth employees training because the less automated process, the higher qualification of each employee has to be, becomes more difficult to replace him in case of illness or dismissal, and even to fill the position becomes a problem! Separate item of expenditure is generally imperceptible materials such as: paper for printing documents and cartridges for printers. It would be nice to recall about garbage removal.

The list above lists only the actual cash costs, but there is also a problem of filling the working time! Many enterprises start every morning printing kilometers of documentation on the planned products, then printed pack, which is up to 5 centimeters thick, carried to workplaces. Sometimes the sheets are confused, and employees run from place to place in search of current task or assort the whole pack. Sometimes for saving, the task on a concrete product is printed on one sheet, where one side is intended for a saw and welding machine, and the other, for example, for workers of fitting station.

Is that all? Unfortunately, in the real world Logistics makes its own adjustments. How to deliver the sawed profile for a product? Where should the welding section search for it after delivery? Where to store it? What product belongs this piece of profile found on the conveyor? It is necessary to ask the senior of the previous shift, but they’ve just went home having submitted the cases to the following shift.

Moment of truth arrives when reflecting on above list you’re taking calculator and starting to figure out how much do you lose in a month. In a quarter? In a year? Most often figures unpleasantly surprise, after all it is about direct loss of the company, and not only direct but also in the form of the missed profit! Any competitor able to show prices lower than yours, with less production time will receive client’s interest and your sales managers will have to make improbable efforts to return him.

All companies have to solve the complexities listed above, regardless of size and turnover. Nowdays formed and successfully applied a systematic approach to solving each problematic item. The decision represented by the KSTsoft company is based on ideas of the Toyota company. The system called “Lean Production”. Provided measures were so effective that helped the “Toyota” company to overcome crisis, significantly increase profits and get closer to the title of best-selling brand in the world!

“Paperless production” is a development which is successfully used by a set of the enterprises allover CIS. Created in the closest cooperation with the largest Russian producers and tested strictly in real leading enterprises our software allows you to raise the quality of your production to new heights! The reason for this bloc’s incredible success is careful, phased approach to causes elimination of each production’s defect. Implantation is carried out under the supervision of competent professionals with significant experience in organizing successful productions.

Let’s take an overview look at the main (but not all) features of “paperles production’s” use.

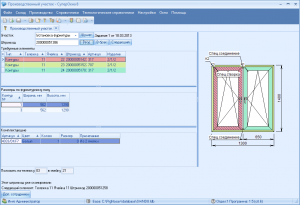

Each component of a product has to be documented. It can seem to be difficult and expensive process, but actually, everything is much simpler than it sounds. Labels required for marking parts of the structure are printed by machines thanks to the uploading system to CNC. Each sticker allows you to obtain the necessary information for each production site.

|

|

Intrashop logistics is optimized by using improved trolleys. The special design of the compartments allows to isolate specific structures and eliminates confusion. In unlikely case of an error, belonging of a particular part to a concrete product can be installed by reading the bar-code or the information on the label. The procedure for filling the trolleys is calculated in advance to avoid the lay-up and need of search of different structure parts on trolleys.

The next point in the fight against overruns is refusal of printed documentation. The employee holds the scanner by a label of, for example, profile’s piece and the screen immediately displays all the necessary steps for the specific workplace: where to take the rest necessary parts, how to arrange them in machine’s grips, the further will be executed by machine itself. If your machine is not enough “smart” to handle the product according to uploading then the computer screen in detail, in pictures, will explain employee the steps which he need to produce, what sizes to operate and how to arrange the product.

Such approach virtually eliminates human errors like “didn’t cut”, “didn’t put”, “forgot what to do”, “looked wrong listing”.In most cases, even to mix up the segments will be extremely difficult. However, let us assume that an error happened. Spoiled product may be rejected and it will have no effect on the further process, the rest departments will immediately know that they don’t need to do work on parts of rejected product and should move on to other works.

The personal responsibility of the staff member is achieved by using the personal bar-codes and procedures of product’s passing through departments. Registration on a workstation, other than access to the program can serve as a basis for piecework wage, because the operations performed by a particular employee can be easily estimated in monetary terms. Each stage has a person of a particular specialist, that increases the grade of execution of works.

Let’s briefly discuss the interesting feature of the bloc: planning of production. It’s convenient to consider the shift as the time period, though nothing stops you to choose another one. Products which were decided to make during shift, unite in the form of production target. Any number of designs from any orders can be included to it. Congratulations, the most difficult part is done! Most of follow-up actions are performed by pressing the corresponding buttons. To make a full cutting of products? One button. To prepare documentation? Another button. To upload tasks to the CNC? The third one. Almost all of the work the bloc will perform automatically. Creating production tasks for some considerable period of time, you can effectively boot the production by required scope of work, and devote time to improving quality of manufactured products. There is nothing better for the company, than to considerably surpass competitors at the quality of production. By the way, the better product, the less reason to lower prices!

We want everyone to know: Unlike many companies, we do not allow ourselves to experiment with your production and try to use solutions proven by the most successful and renowned companies. A unique feature of our researches is their focus on the profitability of your business, because future of our company depends on your well-being. To keep the quality of our software and services at the highest level, we carefully train employees, keep in touch with the majority of machinery manufacturers, We attend the organization of production and conduct thorough analysis of the technological innovations and methods of factory’s creation. The bloc of “Paperless production” is a unique elaboration because it starts to pay off right from the moment of start. Join the most successful companies of the world and the CIS! “Paperless production” is the only possible way of development.

In the design used photos of the production of our customers and the images presented http://www.sxc.hu